Innovative solutions for dust and spillage challenge

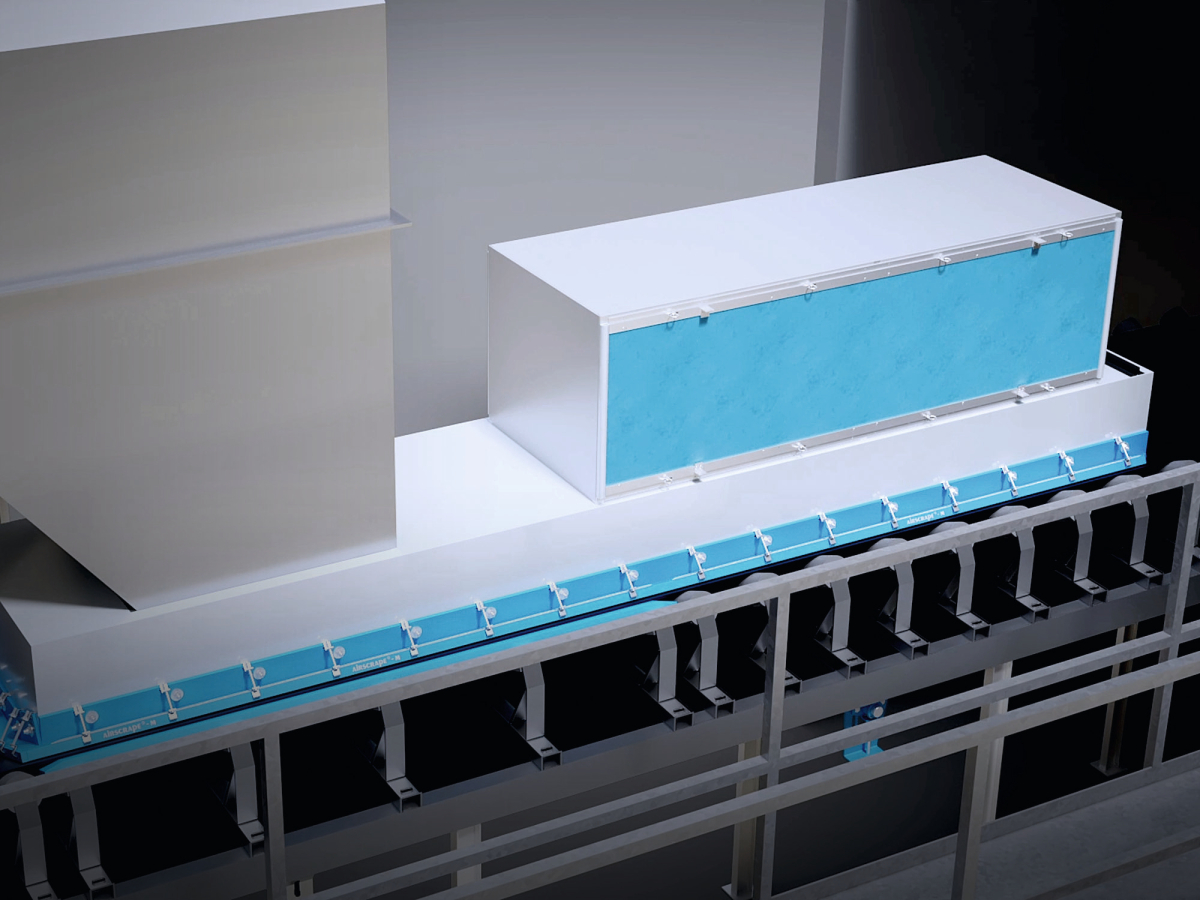

1 AirScrape

1 AirScrape © ScrapeTec The AirScrape offers a variety of strengths and advantages. It effectively reduces dust and spillage, regardless of the materials used. Whether it’s fine particles or coarse bulk materials, the AirScrape tackles every challenge. Its specially designed sealing technology ensures that dust and spillage are retained at the source and do not spread throughout the entire conveying process. This leads to improved cleanliness, reduced environmental impact, and increased workplace safety.

The DustScrape is another outstanding solution by ScrapeTec, designed to combat dust problems and excessive pressure during transfer. It serves as a cost-effective alternative to expensive dedusting systems. Whether dealing with sensitive materials prone to dusting or abrasive materials that can cause wear, the DustScrape provides an effective solution.

Both the AirScrape and DustScrape have proven their worth in a wide range of industries and applications. They are used in mining, cement industry and many other fields. With the AirScrape and DustScrape, ScrapeTec offers innovative solutions for dust and spillage problems. They contribute to improving working conditions, environmental compatibility, and the efficiency of conveying systems. And if an expensive active dedusting system is already installed, the installation of the DustScrape can now also greatly reduce the energy and maintenance costs of this dedusting system.