Dry mortar produced according to the state of the art

Oradea – a town in Northwestern Romania, near the Hungarian border, is the birthplace of Adeplast, a Romanian group of companies. In 1996, Marcel Barbut became the majority shareholder of the company established in 1994 under the name Multistar Prod S.R.L. and transformed it into a Romanian-Austrian company. The link to Austria is obvious with Marcel Barbut – after all he worked many years in Austria and, as he says, he learned a lot there. Focus of the company, which sells its products under the brand name Adeplast®, is the production of adhesives for ceramic cladding, polishing plasters, floor levelling compounds, industrial floor tiles and mechanically applied mortars.

From then on, the company began to grow. In 2004 a dry mortar factory was opened in Oradea. In the meantime, the Group owns three production sites, which, located in a large triangle, can supply the entire Romanian territory.

Oradea with a production capacity of 250 000 t dry mortar and adhesives, 50 000 t paints and decorative plasters per year and 700 000 m3 expanded polystyrene (EPS) – the first plant in the group in companies. In addition the northwestern site is the only site at which grey polystyrene is produced in collaboration with BASF.

Ploiesti is located near Bucharest in Southern Romania, with a capacity of 450 000 t dry mortar and adhesives, 700 000 m3 EPS and 50 000 t paints and enamels per year. The dry mortar plant went into operation in 2008.

The latest site is located in Roman, up in the northeast of the country. With the opening of the third site in August 2013, Adeplast became the Number 1 manufacturer of thermal systems in Romania. 450 000 t adhesives and dry mortars and 700 000 m3 EPS will be produced here in future when the plant is operating at full capacity. Initial difficulties with one of the main water pipes running through the site for the supply of Roman needing to be moved did not deter Marcel Barbut: “Problems are there to be solved.” Following the successful installation of sand drying and processing plant in Oradea, Barbut chose the Austrian company BT-Wolfgang Binder GmbH as a general contractor. The plant completed in just five months or 15 to 20 000 assembly hours is one of the most modern dry mortar plants. One month after commissioning, production began in August 2013. In the meantime 65 people work at the plant in Roman.

The dry mortar plant has two production lines: one for cement-bonded and one for gypsum-bonded products. The daily production capacity is 1000 t/shift, 60 % cement-bonded and 40 % gypsum-bonded products being produced.

One of the most important starting materials for the production of dry mortar is sand in different grades. This is supplied from sand pits, with a moisture content of 8 to 10 %. In the sand storage, in which up to 3000 t can be stored, the upper layers of sand dewater to a water content of 5 %. The rest is done by a vibrating dryer/cooler, which dries 50 t sand per hour to a moisture content of 0.2 % and cools it to below 50 °C. Continuous moisture measurement at the belt feed to the dryer/cooler and at the dryer/cooler discharge constantly delivers actual values, which are then used to optimize the dryer control by means of the central plant control system and helps to save energy.

Upstream of the dryer, the sand is sent via a distributor feeder so that the entire width of the dryer is utilized. Drying is performed at a temperature up to 500 °C.

The gas burner is controlled either externally by means of the central plant control system or directly from a burner control cabinet.

At the dryer/cooler discharge, the sand is sent over a lump screen to remove stones and other large impurities. A bucket conveyor is used to feed the sand into the tumbling screens and the screened sand is fed in discharge pipes into the appropriate sand silos.

The remaining raw materials and binders are delivered by truck and injected into silos or storage containers via injector pipes. The additives are supplied in big-bags or sacks and transported onto the platform by means of lift and hoisting equipment and then filled manually into the respective tanks. At the silo heads and additive tanks, there are silo top filters/bag filters for dedusting.

A total of 11 silos are available for the cement binder and 14 silos for the gypsum line. The raw materials are removed by means of a metering screw into the weighers and combined in the mixer according to the recipe. All screws are equipped with frequency converters for precision-accuracy metering.

Every line has two main weighers and two smaller weighers for weighing the additives and one large and one small manual feed. When components have to be manually added, this is displayed on a terminal in the area of the manual feed. The weighers are uncoupled from the cover by means of a compensator, with the lower tare weight of the weigher, a higher weighing accuracy is achieved. By means of plant control, the recipe, metering sequence and mixing time are defined. In addition, for every mixture, a log is saved, so that later all mixtures can be traced in the event of a complaint.

Downstream of the mixer, the material enters a rotary distributor head – here the decision is made whether the material should go to the sack-filling plant (15 - 40 kg valve sacks), in small packages (1 - 5-kg sacks or big bags) or for truck loading. Depending on the type of packaging, the mixture is further transported in the storage tank for the inline packers or on a belt conveyor for loose loading.

The filled sacks then go automatically to two palletizers – one line for gypsum- and one for cement-bonded building materials. In the fully automatic plant 40 t/h or 40 pallets/h can be packed in each case. Before being palletized, the sacks are compressed so that they take up the smallest possible volume. In this step, especially the de-airing capacity of the sacks is very important.

With regard to plant control, BT-Wolfgang Binder GmbH works together with the Austrian control engineering company ESA Elektronische Steuerungs- und Automatisierungs-GmbH. The software modules developed for this purpose run on current Microsoft operating systems and are connected to an MS-SQL database. With this, it is possible to connect to ERP systems and external plant components, like, for example, a packaging or palletizing plant.

All production data is reported direct from the individual stations to the database and managed there. Full transparency and control in all production steps from the acceptance of raw materials to processing of the finished products is ensured. Intelligent recipe management with unit-related contamination matrix is part of the overall plant control. This automatically prevents, for instance, that after the production of coarse or dark products, no fine or white products can be produced without a cleaning cycle being performed first.

To ensure the correct function of the plant, the technical documentation for every machine and a maintenance programme are integrated in the process control. This automatically reminds the plant operator of any maintenance due. This gives both the plant operator and BT-Wolfgang Binder the certainty that maintenance is performed regularly.↓

During a visit to the factory, Dr Petra Strunk, Editor-in-Chief of AT MINERAL PROCESSING, took the opportunity to talk to Mr. Marcel Barbut, majority shareholder of Adeplast®.

AT MINERAL PROCESSING: Adeplast – what’s behind the name?

Marcel Barbut: Adeplast is a Romanian-Austrian company established by me and a partner in 1994. Over the years, Adeplast has developed into a leading supplier in the building materials sector in the Romanian market and neighbouring countries.

AT MINERAL PROCESSING: At the Roman site in Eastern Romania a new dry building materials plant went into operation one year ago. You selected BT-Wolfgang Binder GmbH as the general contractor for the construction of the new plant – what reasons did you have for this choice?

Marcel Barbut: Adeplast has experienced rapid growth in the last years, and several new plants and productions sites have been built. On account of many less than positive experiences with the previous new factory builds, this time we decided to award the contract for the construction of the new dry building material plant to a general contractor. A general contractor is responsible for everything – from concept development to commissioning of the plant, so that we didn’t have anything to do with the individual steps and the coordination of the scheduled dates.

Some time earlier, BT-Wolfgang Binder had successfully built a drying and sand processing plant for another Adeplast facility. In addition BT-Wolfgang Binder has lots of references in the building materials sector, in which it had proven itself a competent plant engineering company. The decision to realize this project with BT-Wolfgang Binder was correct – despite lots of problems with the local authorities, we got the plant up and running on time and to this day, one year after it was commissioned, there have been no serious faults or problems and we have been able to supply all our customers on time with our Adeplast products in their usual quality. For the construction work and the concrete engineering we contracted a Romanian-German building firm, whose work was also excellent.

AT MINERAL PROCESSING: How does the planning phase work with a general contractor?

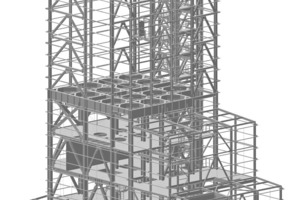

Marcel Barbut: We gave BT-Wolfgang Binder all key data like the number and type of raw materials and necessary throughput rates. In a number of project talks, we developed the plant concept together with BT-Wolfgang Binder. The ideas of Adeplast and the ideas of BT-Wolfgang Binder were fused into a joint concept. ln this project phase, the 3D design presentations from BT-Wolfgang Binder really helped us. Already in an early stage of the project, thanks to these 3D images, we were able to see the design with many realistic details and BT-Wolfgang Binder was able to take the wishes and requirements of technicians into consideration in the plant design.

Here the two models for the detailed steel engineering design and detailed machine design are nested so that collisions for pipelines, chutes and plant components with beams, supports, steel engineering assemblies are absolutely ruled out. This was particularly important for a lot of the material feed lines and cross connections between mixers and weighers.

AT MINERAL PROCESSING: What further investments are planned in dry building materials?

Marcel Barbut: With the existing production sites, we are able to supply the Romanian market very effectively and respond to customer requirements fast and efficiently. I have four sons, two of whom are already working in the company – we want to expand and I hope that my children will continue the business.

Naturally, increasing export of the products and production sites abroad are a goal for the future. We already have contacts to Saudi Arabia and Kuwait, there we supply materials from the plant in Ploiesti. These countries are, however, relatively small. As soon as we have market shares in these countries, we are thinking about using the MODULANLAGEN modular plant system from BT-Wolfgang Binder. This type of plant is relatively low-priced in terms of acquisition costs and it is possible to start production almost immediately. That is a super possibility.

AT MINERAL PROCESSING: How has Adeplast been able to grow steadily despite the crisis times?

Marcel Barbut: We started up four plants last year. We are very good and effective in production, i.e. with regard to revenue per employee. We have good sites with an optimum geographic distribution over Romania. If the customers have a problem, they can ring us – we’re always there for them. Up until two years ago my personal telephone number was printed on the sacks in case someone had a question or a problem. Naturally, we also visit the customers and test the respective material and show them how to use it properly. So that in the end the customers are really satisfied with the result.

AT MINERAL PROCESSING: Many thanks for this interesting talk!

//www.adeplast.ro" target="_blank" >www.adeplast.ro:www.adeplast.ro

Autor/Author: Dr. Petra Strunk